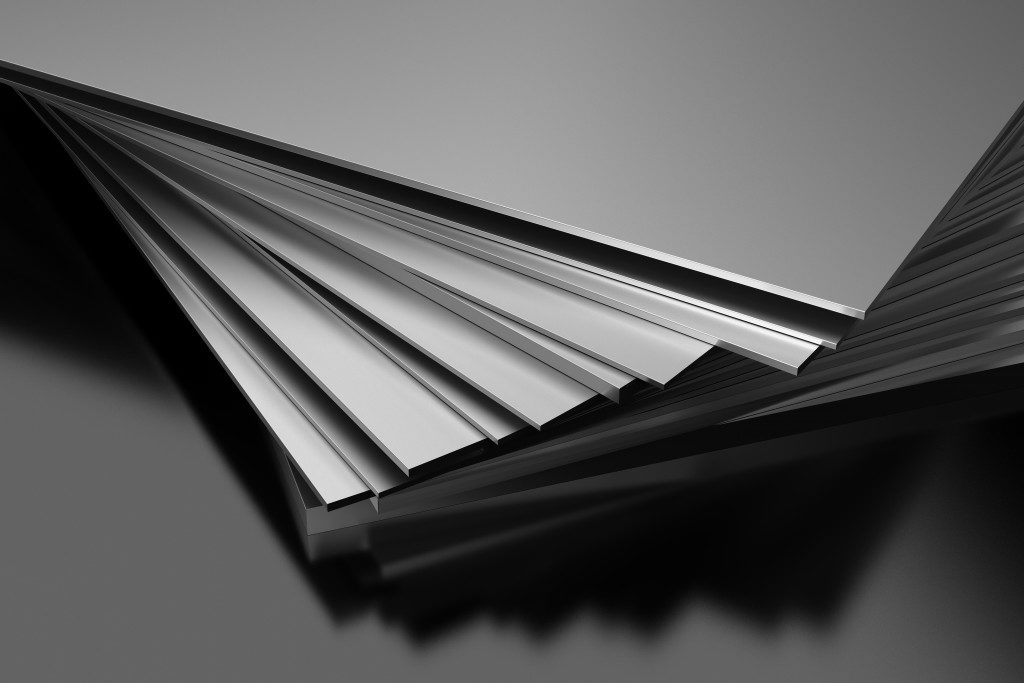

Sheet metal forms the majority of our metal components when it comes to machinery, automobiles, hobbies, and buildings. Versatile, malleable, and easily workable, sheet metal has gone a long way from being bashed with hammers to the essential metal we use in construction today.

The beauty of sheet metal is that it can be made out of any type of alloy or combination of metals. If you’re curious about the other types of metals you can use with your Baileigh bead roller aside from pure steel sheets, you can consider the following:

Stainless Steel

While normal steel is the most common sheet metal that we manufacture and use today, stainless steel is undoubtedly the best material you can work with. In terms of beading, the alloy is very good at maintaining its shape under pressure, and can be welded easily.

Common uses of stainless steel would include cutlery, medical equipment, piping systems, or any application that involves prolonged and regular contact with liquids. The resistance to rust or corrosion of stainless steel makes it a metal of choice in most industries today.

Brass

Brass sheets are somewhat of a special outlier when it comes to their use and application. A more developed form of copper metal, it’s more durable, malleable, and resistant to corrosion while maintaining the electrical conductivity of copper. This makes it ideal for use in large-scale electrical operations.

However, working with brass on a very small scale may not be very profitable due to the inherent unpredictability of the material under high pressures or temperatures. It’s best to leave brass-related orders aside unless you have the equipment required to deal with it; otherwise, you’re risking a poor product.

Aluminum

Aluminum is one of the most resilient and popular sheet metals out there, given the varying thicknesses and uses that spring from its construction. Cost effective, easily recyclable, and often treatable with different finishes and compounds, aluminum is among the most common metals any metalworker has ever handled.

Applications vary depending on the gauge (or as it’s internationally measured, the thickness), ranging from decorative jewelry to pressure vessels. One of the best features of aluminum is how easy it is to change given the right treatment and thickness, making it a metal of choice for many industries today.

All of these metals work well in a bead roller, but the most important thing to keep in mind is the purpose of the final product, the die that you use, and the overall gauge or thickness of the metal. As a general rule, aluminum is one of the best metals to bead given the variety of grades that can be easily molded to size anything, while brass generally falls under the category of precision work.

Sheet metal should be an integral part of every metalworker’s shop, as it’s one of the easiest raw materials to handle and work with. Good metalworkers will even have sheets of their own around the shop for reference or practice. It’s no doubt sheet metal will remain a useful material for construction.