- Manufacturing costs are affected by inefficient production, excessive energy use, and high maintenance costs.

- Excessive use of raw materials and limited automation also drive up manufacturing costs.

- Regular maintenance and investment in efficient equipment can significantly reduce manufacturing costs.

- Streamlining inventory management and automating processes can optimize productivity and minimize waste.

- Making data-driven decisions using analytics can offer insights into reducing costs and enhancing profitability.

Manufacturing businesses often face numerous hurdles when boosting their revenue stream. Manufacturing costs are among the most significant factors affecting such businesses’ margins. Even with a fully functioning and optimal factory, high costs often find a way of cropping up and reducing profit margins. So, what could be the factors causing the high manufacturing costs? Here’s a look into the manufacturing industry, how your factory costs your business, and how you can deal with it.

The Manufacturing Industry Today

The manufacturing industry in the U.S. is estimated to be worth $2 trillion. Despite the growing economy, several issues hinder businesses’ overall profitability in the manufacturing industry. One of them is the factories.

Reasons Your Factory Costs You Money

There are numerous reasons why your factory costs you money. Here are some ways:

1. Inefficient Production Processes

One of the most significant impactors of manufacturing costs is the efficiency of the production process. Slow production, frequent breakdowns, and unproductive staff can increase the time and resources, increasing production costs. Therefore, it is vital to create a comprehensive plan for improving the efficiency of your production processes. This could involve training your staff and investing in better equipment that guarantees minimal downtimes and proactive maintenance programs.

2. Excessive Energy Usage

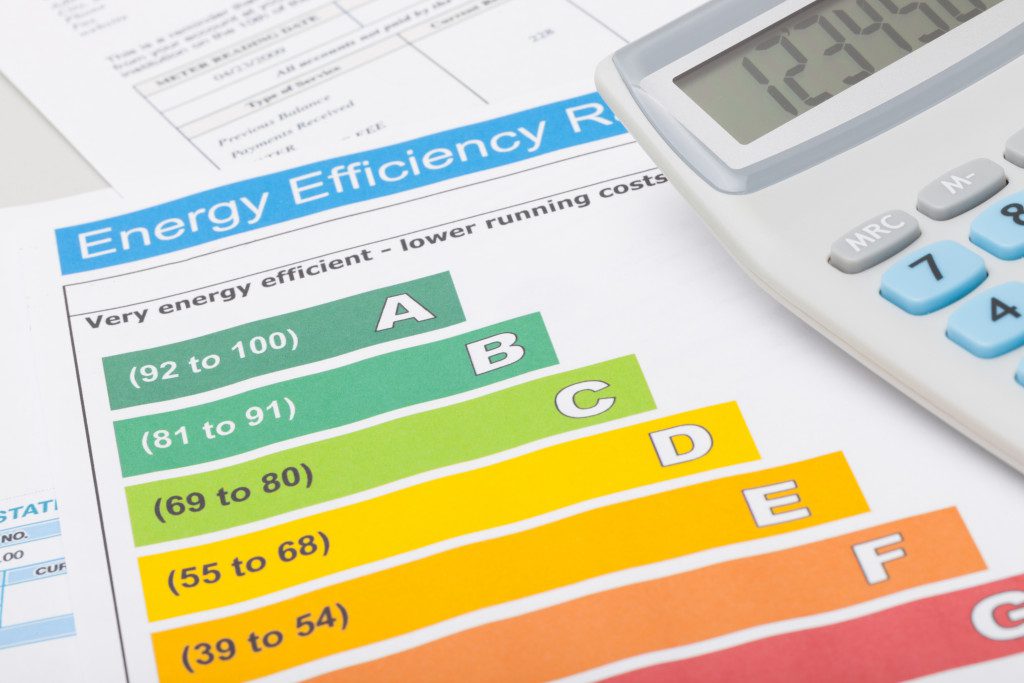

Manufacturing companies typically consume vast amounts of energy, resulting in high energy bills. In addition, outdated equipment and inefficient processes use more energy than necessary, leading to excessive bills.

3. High Maintenance Costs

Factories and equipment require constant maintenance to operate efficiently, often resulting in high maintenance costs. These include parts replacement, repair and inspection fees, and labor costs. It can affect your business over time, leading to bankruptcy if not controlled properly.

4. Excessive use of Raw Materials

Another factor that could be costing your manufacturing business is the excessive use of raw materials. Overproduction, inaccurate forecasting, and inadequate management of stock levels all add up to higher material costs.

5. Limited Automation

Automation in the manufacturing industry has significantly lowered the cost of production, minimized errors, and improved efficiency. By limiting automation, your factory could be costing your manufacturing business more than you realize.

Ways to Improve Your Factory

Improving your factory doesn’t have to be a daunting task. Here are five ways you can reduce manufacturing costs:

Proper Maintenance

Your factories are home to various hydraulic machines, which are subject to wear and tear. Regular maintenance keeps them running optimally, efficiently, and safely. To drastically reduce the cost of this maintenance, consider partnering with a local hydraulic machinery repair service. The service can check the hydraulics of your machinery and take care of any necessary repairs or replacements.

Invest in Efficient Equipment

Investing in more efficient equipment can help you to reduce energy consumption and cost. Choose energy-efficient machines, such as high-efficiency HVAC systems, LED lighting fixtures, water filters, and automated processes. You should also consider investing in renewable energy sources like solar panels and wind turbines.

Streamline Inventory Management

Inventory management is essential for reducing material costs and optimizing production processes. You can quickly track inventory levels and receive up-to-date stock availability information using the right inventory management system. This will help you better manage your stock levels and reduce unnecessary expenditures.

Automate and Optimize

Automating production processes eliminates the need for manual labor, resulting in fewer errors and faster production. Additionally, implementing optimization techniques can help to improve production efficiency. Consider investing in advanced automation technologies such as robotic process automation (RPA) and artificial intelligence (AI).

Make Data-Driven Decisions

Data analytics is essential for making data-driven decisions in the manufacturing industry. By utilizing data analytics, you can gain insights into your production processes and make informed decisions to reduce costs. This could include reducing material waste, improving equipment efficiency, and increasing staff productivity.

Manufacturing businesses face a unique set of challenges when it comes to sustaining and boosting their revenue streams. However, these hurdles can be overcome through strategic planning and leveraging technology. Regular and efficient maintenance practices and data-driven decision-making can significantly reduce manufacturing costs and increase profitability. Remember, the goal is not to eliminate costs but to manage them effectively to maximize profit margins. In the ever-competitive manufacturing industry, cost optimization isn’t just a choice; it’s a necessity.