It’s no secret that the auto manufacturing industry is in a state of flux. With the advent of new technologies and changing consumer demands, manufacturers are under increasing pressure to customize their products to meet specific needs.

This challenge has led to several changes in how the industry operates, from developing innovative new production methods to a growing focus on customer service and satisfaction.

Here are just a few of the ways that customization is changing the auto manufacturing landscape:

1. New Production Methods

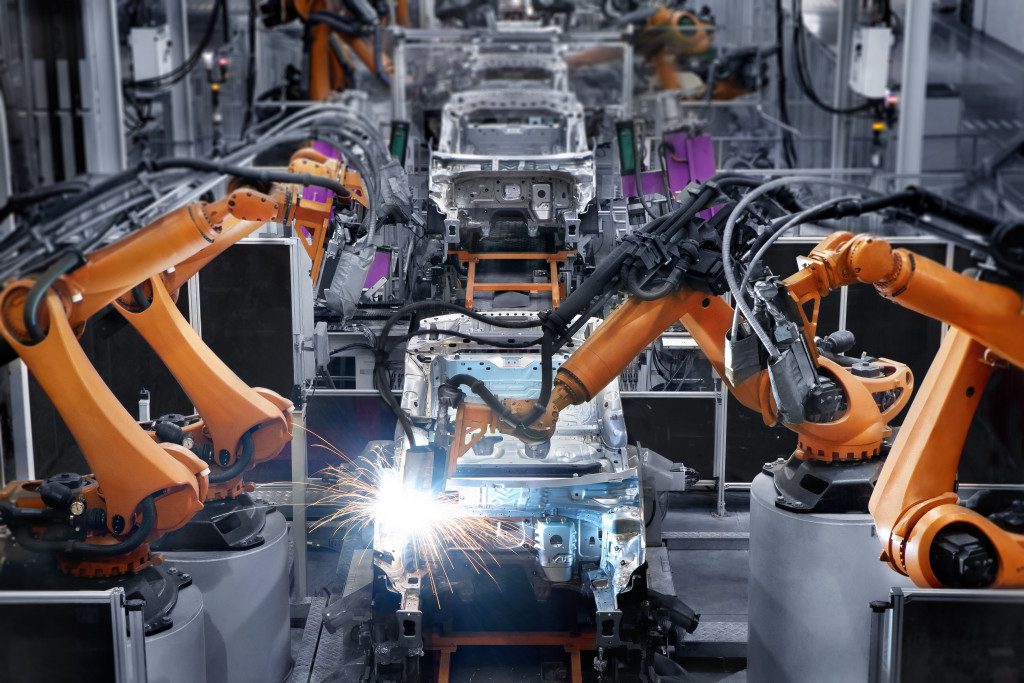

To meet the demand for customized vehicles, manufacturers are working on developing new production methods that will allow them to quickly and efficiently produce vehicles to specific specifications.

This includes everything from 3D printing of parts to using flexible robots that can handle a variety of tasks. Not only does this help manufacturers keep up with customer demand, but it also allows them to produce vehicles more cheaply and efficiently.

2. Increased Focus on Customer Service

With customers now expecting a high level of customization, manufacturers are placing a greater emphasis on customer service and satisfaction. This means offering a wide range of options for customers to choose from and providing support and guidance through the ordering and production process.

It’s also becoming increasingly common for manufacturers to offer post-purchase customization services, such as installing aftermarket parts or making modifications to the vehicle itself.

3. Improved Quality Control

As vehicles become more complex and customizable, it’s essential for manufacturers to maintain strict quality control standards. This includes everything from ensuring that parts are made to specification to performing regular checks during the production process.

By doing this, manufacturers can ensure that each and every vehicle meets the customer’s expectations and leaves the factory floor in perfect condition.

4. Greater Emphasis on Auto Marking

As customization becomes more commonplace, metal marking fluid is playing an increasingly important role in auto manufacturing. This type of fluid helps to create more precise and consistent markings, making it easier for manufacturers to meet the needs of their customers.

This fluid is a specialized type of ink that is designed specifically for use on metal surfaces. It can be used to create a variety of different markings, including logos, serial numbers, and even barcodes.

5. More Flexible Manufacturing Processes

To accommodate the growing demand for customization, manufacturers are working to make their production processes more flexible. This includes making changes to the assembly line itself, as well as introducing new technologies that can help with the customization process.

For example, some manufacturers are now using laser cutting machines to create custom parts for vehicles. This allows them to produce parts quickly and efficiently without having to rely on traditional manufacturing methods.

6. Greater Use of Data and Analytics

With customization becoming more important, manufacturers are collecting more data than ever before. This data is then used to help make production decisions and understand customer preferences and trends.

Data and analytics also play a role in post-purchase customization, with manufacturers using this information to offer customers tailored services and products.

7. Improved Sustainability Practices

Every business wants to be more sustainable, and the auto industry is no different. As customization becomes more prevalent, manufacturers are working to find ways to reduce waste and improve their environmental practices.

One way that manufacturers do this is by using recycled materials to produce parts and components. This helps to reduce the amount of waste generated while also saving money on production costs.

Another way that manufacturers are becoming more sustainable is by offering customers the option to purchase eco-friendly vehicles. These vehicles often use alternative fuel sources, such as electricity or biodiesel.

8. Greater Use of Technology

Customization is changing the auto industry in several ways, but one of the most important is the increased use of technology. This includes everything from 3D printing to virtual reality, and it plays a major role in how vehicles are designed, built, and sold.

3D printing, for example, is being used to create custom parts and components for vehicles. This allows manufacturers to produce parts quickly and efficiently without relying on traditional manufacturing methods.

There you have it: eight ways that customization is changing auto manufacturing. You can now see, this trend is having a major impact on the way that vehicles are designed, built, and sold. So, if you’re in the market for a new car, be sure to keep these changes in mind. Also, don’t be afraid to ask for what you want – chances are, the manufacturer will be able to accommodate your request.